Are you fascinated by manufacturing and eager to build a career that shapes the world around you? The field of precision machining is a dynamic and essential sector, quietly underpinning countless aspects of modern life. If you’re exploring skilled trades, understanding precision machining—and how to build a Career Calibrating Precision Machine Tools—could be your first step towards a rewarding and in-demand profession. Let’s delve into this critical field, explore what it means to work with precision, and how you can embark on a machining career path.

Precision machining is fundamentally about accuracy. It’s a manufacturing process that meticulously removes material from a workpiece to create a finished part with incredibly tight tolerances and precise surface finishes. Imagine taking a block of raw material and, through careful and controlled processes, transforming it into a component that fits perfectly within a larger machine or system. That’s the essence of precision machining. This intricate shaping process employs techniques like cutting, milling, turning, and electrical discharge machining (EDM), often utilizing sophisticated Computer Numerical Control (CNC) equipment to achieve unparalleled accuracy and repeatability.

The impact of precision machining is far-reaching. From the smallest components in your smartphone to massive parts in aircraft engines, precision machined parts are everywhere. Consider the intricate workings of an automobile, the delicate instruments used in surgery, or the robust components of space shuttles – all rely heavily on precision machining. Even the tools and machinery used in other manufacturing processes often require machine tool calibration and maintenance by skilled precision machinists. In essence, if a product is composed of parts, precision machining has almost certainly played a role in its creation.

To excel in precision machining, a keen eye for detail and a strong understanding of technical drawings are crucial. Precision machinists work with blueprints generated by Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software. These programs create detailed 3D models and instructions that guide the machining process. These blueprints are not just guidelines; they are precise roadmaps that must be followed meticulously to guarantee the quality and functionality of the final product. While digital blueprints are the norm, the initial design phase may still involve hand-drawn sketches, highlighting the blend of traditional skills and cutting-edge technology in this field.

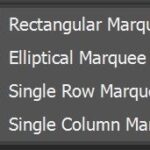

Precision machinists are versatile material experts. They work with a wide spectrum of materials, including various metals like steel, bronze, and graphite, as well as plastics, glass, and composites. The specific tools and techniques employed in precision machining are dictated by the project’s scale and the materials involved. A skilled machinist must be proficient in operating a diverse array of equipment, from drill presses and grinders to lathes, milling machines, saws, and even advanced robotic systems. The ability to master and combine these tools and processes is key to success in this dynamic field.

Launching Your Career Calibrating Precision Machine Tools

Precision machining is a specialized area within the broader field of CNC machining and programming. Therefore, aspiring precision CNC machinists need a solid foundation in CNC technology. However, simply knowing how to operate a machine is no longer sufficient. Modern employers actively seek certified, well-trained, and formally educated CNC machinists to join their teams. This emphasis on qualifications underscores the increasing complexity and technological advancements within the industry.

For those seeking formal training, numerous educational pathways can lead to a fulfilling career calibrating precision machine tools and working in precision machining. Look for programs that offer a blend of theoretical knowledge and practical, hands-on experience. A comprehensive curriculum should cover:

- Technical Drawings and Blueprint Reading: Essential for interpreting design specifications and understanding part requirements.

- Material Properties and Metalworking Theory: Provides the foundational knowledge to select appropriate materials and machining techniques.

- Product Specifications and Quality Control: Ensures parts meet stringent quality standards and tolerances.

- Computer-Aided Machining (CAM) and CAD Software: Mastering these digital tools is crucial for modern precision machining.

- Machine Tool Calibration Principles: Understanding the importance of calibration and learning the techniques to ensure machine accuracy – a highly valuable specialization.

Beyond technical skills, successful precision machinists also possess crucial soft skills. Employers value individuals who demonstrate:

- Excellent Communication Skills: To effectively collaborate with engineers, designers, and other team members.

- Problem-Solving Abilities: To troubleshoot machining challenges and optimize processes.

- Adaptability and a Growth Mindset: The field is constantly evolving, requiring a willingness to learn new technologies and techniques.

The Future is Precise

A career calibrating precision machine tools and working in precision machining offers a stable and rewarding path in a technologically advanced industry. As manufacturing continues to evolve, the demand for skilled precision machinists will only increase. By acquiring the right education, technical expertise, and soft skills, you can position yourself for a successful and impactful career shaping the future of manufacturing. Explore training programs in your area and take the first step towards a precise and promising future.