For car owners and DIY enthusiasts, the On-Board Diagnostics II (OBD II) system is a game-changer. It’s like having your car communicate directly with you, pinpointing issues through a system of Obd Ii Scanner Trouble Codes. When your vehicle’s computer detects a problem, it logs a Diagnostic Trouble Code (DTC) in the Engine Control Unit (ECU) memory. By plugging an obd ii scanner into your car’s OBD port, you can access these codes and begin to understand what’s ailing your vehicle.

These codes aren’t random gibberish; they follow a structured format, offering valuable clues about the problem even before you consult a detailed chart. Let’s break down how to decipher these obd ii scanner trouble codes.

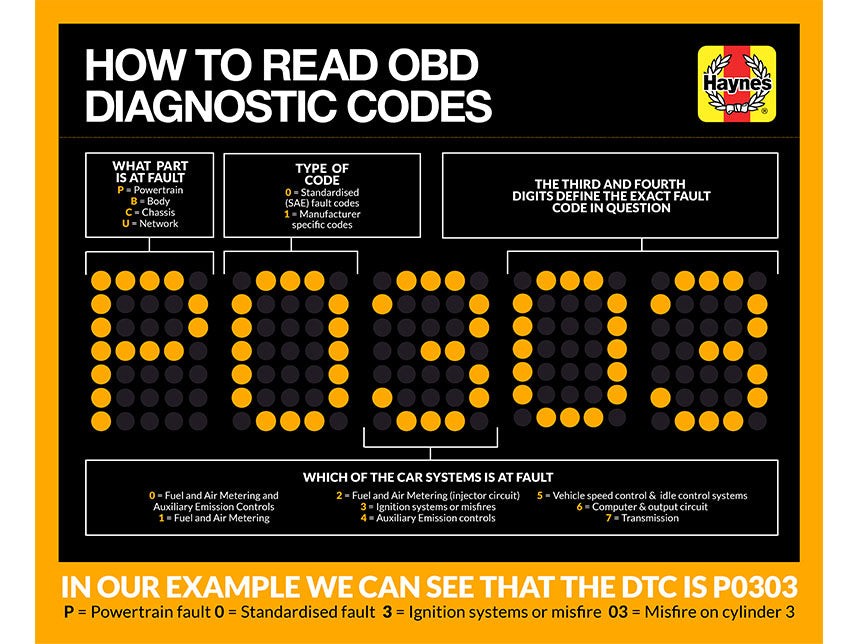

Understanding the Anatomy of OBD II Trouble Codes

Every obd ii scanner trouble code is composed of five characters: a letter followed by four numbers. Each position provides specific information about the fault.

The Initial Letter: System Identification

The first letter of the code indicates the primary system affected:

- P (Powertrain): Relates to the engine, transmission, and associated drivetrain components. These are the most common obd ii scanner trouble codes.

- B (Body): Concerns body-related systems like airbags, power windows, and electronic accessories.

- C (Chassis): Indicates issues with chassis systems such as braking, steering, and suspension.

- U (Network): Signifies problems with the vehicle’s communication network, often involving the Controller Area Network (CAN) bus.

The First Number: Code Type

The first numerical digit clarifies whether the code is a standardized or manufacturer-specific fault:

- 0: Indicates a standardized or generic SAE (Society of Automotive Engineers) code. These obd ii scanner trouble codes are common across most makes and models.

- 1: Signifies a manufacturer-specific code. These codes are unique to a particular car manufacturer and may offer more detailed information about the fault than generic codes.

The Second Number: Subsystem Category

The second numerical digit pinpoints the specific subsystem within the broader system identified by the first letter. For Powertrain (P) codes, the categories are:

- 0: Fuel and Air Metering and Auxiliary Emission Controls

- 1: Fuel and Air Metering

- 2: Fuel and Air Metering (injector circuit)

- 3: Ignition systems or misfires

- 4: Auxiliary emission controls

- 5: Vehicle speed control & idle control systems

- 6: Computer & output circuit

- 7: Transmission

The Final Numbers: Specific Fault Identification

The third and fourth digits provide the most granular detail, specifying the exact nature of the fault within the identified subsystem. These numbers, in conjunction with the preceding characters, lead to a precise obd ii scanner trouble code definition.

Example: Decoding P0303

Let’s take the example code P0303 and apply our understanding:

- P: Powertrain fault – indicating an engine or transmission related issue.

- 0: Standardized fault code – meaning this is a generic code defined by SAE standards.

- 3: Ignition systems or misfires – narrowing down the problem area to ignition or engine misfires.

- 03: Specific fault – in this case, indicating a misfire detected on cylinder number 3.

Therefore, P0303 translates to a Powertrain, standardized code indicating a misfire specifically on cylinder 3. This level of detail from a simple obd ii scanner trouble code is incredibly helpful for diagnosing car problems efficiently.

Decoding OBD II Trouble Codes: Understanding the structure of diagnostic fault codes read by OBD2 scanners for automotive diagnostics.

Decoding OBD II Trouble Codes: Understanding the structure of diagnostic fault codes read by OBD2 scanners for automotive diagnostics.

Common OBD II Trouble Codes Chart

While understanding the structure of obd ii scanner trouble codes is crucial, a reference chart is invaluable for quickly identifying common issues. Below is a table listing some frequent OBD II codes and their descriptions. Keep in mind that not all codes apply to every vehicle model, and manufacturer-specific codes will require further research.

| Code | Code Identification |

|---|---|

| P0101 | Mass air flow (MAF) sensor circuit, range or performance problem |

| P0102 | Mass air flow (MAF) sensor circuit, low input |

| P0103 | Mass air flow (MAF) sensor circuit, high input |

| P0106 | Manifold absolute pressure (MAP) sensor circuit, range or performance problem |

| P0107 | Manifold absolute pressure (MAP) sensor circuit, low input |

| P0108 | Manifold absolute pressure (MAP) sensor circuit, high input |

| P0112 | Intake air temperature (IAT) circuit, low input |

| P0113 | Intake air temperature (IAT) circuit, high input |

| P0117 | Engine coolant temperature (ECT) circuit, low input |

| P0118 | Engine coolant temperature (ECT) circuit, high input |

| P0121 | Throttle position sensor (TPS) circuit, range or performance problem |

| P0122 | Throttle position sensor (TPS) circuit, low input |

| P0123 | Throttle position sensor (TPS) circuit, high input |

| P0125 | Insufficient coolant temperature for closed loop fuel control |

| P0131 | Oxygen sensor circuit, low voltage (pre-converter sensor, left bank) |

| P0132 | Oxygen sensor circuit, high voltage (pre-converter sensor, left bank) |

| P0133 | Oxygen sensor circuit, slow response (pre-converter sensor, left bank) |

| P0134 | Oxygen sensor circuit – no activity detected (pre-converter sensor, left bank) |

| P0135 | Oxygen sensor heater circuit malfunction (pre-converter sensor, left bank) |

| P0137 | Oxygen sensor circuit, low voltage (post-converter sensor, left bank) |

| P0138 | Oxygen sensor circuit, high voltage (post-converter sensor, left bank) |

| P0140 | Oxygen sensor circuit – no activity detected (post-converter sensor, left bank) |

| P0141 | Oxygen sensor heater circuit malfunction (post-converter sensor, left bank) |

| P0143 | Oxygen sensor circuit, low voltage (#2 post-converter sensor, left bank) |

| P0144 | Oxygen sensor circuit, high voltage (#2 post-converter sensor, left bank) |

| P0146 | Oxygen sensor circuit – no activity detected (#2 post-converter sensor, left bank) |

| P0147 | Oxygen sensor heater circuit malfunction (#2 post-converter sensor, left bank) |

| P0151 | Oxygen sensor circuit, low voltage (pre-converter sensor, right bank) |

| P0152 | Oxygen sensor circuit, high voltage (pre-converter sensor, right bank) |

| P0153 | Oxygen sensor circuit, slow response (pre-converter sensor, right bank) |

| P0154 | Oxygen sensor circuit – no activity detected (pre-converter sensor, right bank) |

| P0155 | Oxygen sensor heater circuit malfunction (pre-converter sensor, right bank) |

| P0157 | Oxygen sensor circuit, low voltage (post-converter sensor, right bank) |

| P0158 | Oxygen sensor circuit, high voltage (post-converter sensor, right bank) |

| P0160 | Oxygen sensor circuit – no activity detected (post-converter sensor, right bank) |

| P0161 | Oxygen sensor heater circuit malfunction (post-converter sensor, right bank) |

| P0171 | System too lean, left bank |

| P0172 | System too rich, left bank |

| P0174 | System too lean, right bank |

| P0175 | System too rich, right bank |

| P0300 | Engine misfire detected |

| P0301 | Cylinder number 1 misfire detected |

| P0302 | Cylinder number 2 misfire detected |

| P0303 | Cylinder number 3 misfire detected |

| P0304 | Cylinder number 4 misfire detected |

| P0305 | Cylinder number 5 misfire detected |

| P0306 | Cylinder number 6 misfire detected |

| P0307 | Cylinder number 7 misfire detected |

| P0308 | Cylinder number 8 misfire detected |

| P0325 | Knock sensor circuit malfunction |

| P0327 | Knock sensor circuit, low output |

| P0336 | Crankshaft position sensor circuit, range or performance problem |

| P0337 | Crankshaft position sensor, low output |

| P0338 | Crankshaft position sensor, high output |

| P0339 | Crankshaft position sensor, circuit intermittent |

| P0340 | Camshaft position sensor circuit |

| P0341 | Camshaft position sensor circuit, range or performance problem |

| P0401 | Exhaust gas recirculation, insufficient flow detected |

| P0404 | Exhaust gas recirculation circuit, range or performance problem |

| P0405 | Exhaust gas recirculation sensor circuit low |

| P0410 | Secondary air injection system |

| P0418 | Secondary air injection pump relay control circuit |

| P0420 | Catalyst system efficiency below threshold, left bank |

| P0430 | Catalyst system efficiency below threshold, right bank |

| P0440 | Evaporative emission control system malfunction |

| P0441 | Evaporative emission control system, purge control circuit malfunction |

| P0442 | Evaporative emission control system, small leak detected |

| P0446 | Evaporative emission control system, vent system performance |

| P0452 | Evaporative emission control system, pressure sensor low input |

| P0453 | Evaporative emission control system, pressure sensor high input |

| P0461 | Fuel level sensor circuit, range or performance problem |

| P0462 | Fuel level sensor circuit, low input |

| P0463 | Fuel level sensor circuit, high input |

| P0500 | Vehicle speed sensor circuit |

| P0506 | Idle control system, rpm lower than expected |

| P0507 | Idle control system, rpm higher than expected |

| P0601 | Powertrain Control Module, memory error |

| P0602 | Powertrain Control module, programming error |

| P0603 | Powertrain Control Module, memory reset error |

| P0604 | Powertrain Control Module, memory error (RAM) |

| P0605 | Powertrain Control Module, memory error (ROM) |

* Note: Not all codes are applicable to all vehicle models.

Conclusion: Empowering DIY Car Diagnostics with OBD II Scanners

Understanding obd ii scanner trouble codes empowers car owners to take a proactive approach to vehicle maintenance and repair. By using an obd ii scanner and deciphering these codes, you can gain valuable insights into potential problems, allowing for informed decisions about repairs. Whether you’re a seasoned DIY mechanic or just starting out, mastering the basics of OBD II codes is a significant step towards keeping your car running smoothly and saving money on unnecessary garage visits.