Excel Computer Aided Regulation Engineering (CARE) software stands as a pivotal Care Engineering Tool in the realm of automotive diagnostics and control programming. Developed to provide engineers and technicians with graphic interfaces, CARE software simplifies the creation of data files and control programs specifically for freely programmable CentraLine controllers. Beyond its primary function, CARE extends its utility to replace traditional LON engineering tools for LonMark compliant devices, making it a versatile solution for a broad spectrum of applications within building management systems and automotive contexts.

Key Features and Benefits of CARE as an Engineering Tool

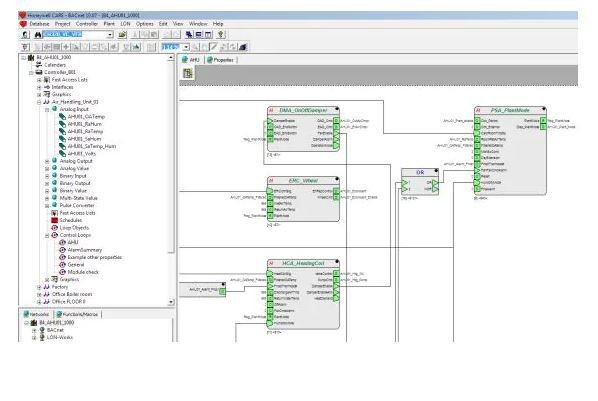

The core strength of CARE lies in its ability to offer graphic tools that streamline complex engineering tasks. This care engineering tool empowers users to visually design and implement control strategies, significantly reducing the learning curve and potential for errors associated with text-based programming methods. Here’s a closer look at the features and benefits that make CARE indispensable:

- Intuitive Graphic Interface: CARE provides a user-friendly environment where control programs are built using graphic elements. This visual approach simplifies the process of creating and managing intricate control sequences, making it accessible to a wider range of professionals.

- Versatile Controller Compatibility: Designed for seamless integration with CentraLine controllers, CARE supports a wide array of systems, including C-Bus and BACnet. It is compatible with various controller series such as Panther, Excel, Tiger, XL500, LION, Falcon, and EAGLE, ensuring broad applicability across different project requirements.

- LON Engineering Tool Replacement: CARE software effectively doubles as a replacement for LON engineering tools, supporting LonMark compliant devices. This capability consolidates tool requirements, reducing complexity and cost for engineers working with diverse communication protocols.

- Enhanced Programming Capabilities: Whether you’re working with C-Bus systems like Excel 80, Excel 100, Tiger (programmable as EXCEL 500), XL500, Excel 600, and LION controllers, or BACnet systems like Falcon and EAGLE controllers, CARE provides the necessary tools to program any application with free programmable controllers from CentraLine.

- Streamlined Data File Creation: Creating accurate and efficient data files is critical for effective control system operation. CARE simplifies this process with its graphic tools, ensuring data integrity and reducing the time required for system setup and configuration.

Applications Across Industries

While initially designed for building management systems, the adaptability and robust features of CARE software make it a valuable care engineering tool in various automotive and related industrial applications. Its precision and flexibility are essential for:

- Automotive Manufacturing: Programming and managing control systems within automotive production lines, ensuring efficient and synchronized operations.

- Vehicle Systems Engineering: Developing and testing control algorithms for various vehicle subsystems, contributing to advancements in vehicle automation and performance.

- Transportation Infrastructure: Managing control systems for traffic management, tunnel ventilation, and other transportation-related facilities, where reliability and precision are paramount.

Conclusion: Embracing CARE for Advanced Control Engineering

In conclusion, CARE software is a powerful care engineering tool that significantly enhances the efficiency and accuracy of control system engineering. Its graphic interface, broad compatibility, and versatile features make it an essential asset for professionals working with CentraLine controllers and LonMark devices across various industries. By adopting CARE, engineers and technicians can unlock new levels of productivity and precision in their projects, ensuring optimal system performance and reliability.

For further information on how CARE can revolutionize your engineering projects, consider exploring the CARE Installation Guide for detailed setup instructions and best practices.