Hello Maxivers! In this article, we’ll delve into a comprehensive guide on how to operate the Flatbed Cutter 5070 TNT digital cutting machine, addressing the initial confusion many users experience. Don’t worry, we’re here to help you become proficient!

Digital cutting machines often amaze users with their performance and flawless precision, especially when compared to earlier models like the Digital Flatbed Cutter 4560. The differences between these two machines are significant, ranging from features to operation.

Key Differences Between Flatbed Cutter 4560 and 5070 TNT

1. Mark Reading System:

- Flatbed Cutter 4560: Employs infrared barcode scanning.

- Flatbed Cutter 5070 TNT: Utilizes camera-based QR Code scanning.

2. Operation:

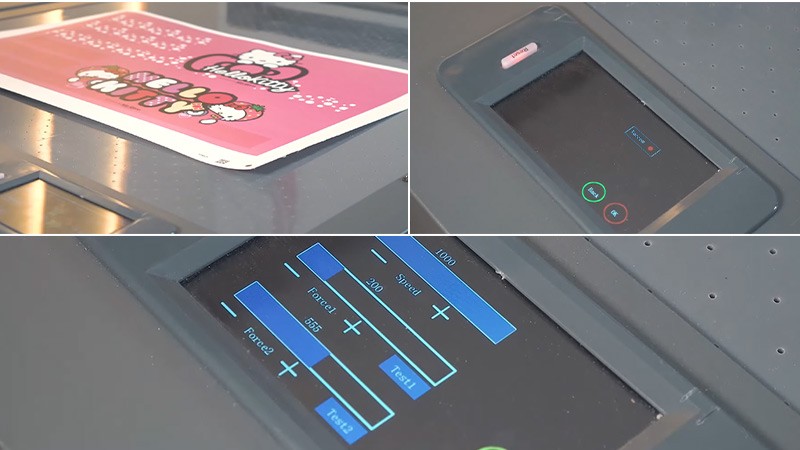

- Flatbed Cutter 5070 TNT: Offers a broader operational scope with diverse menus and features accessible through a touch screen control panel.

3. Bundled Software:

- Flatbed Cutter 4560: Comes with Dragon Cut software.

- Flatbed Cutter 5070 TNT: Is equipped with Cut Tool CDR Cam software, featuring additional tools to streamline the cutting process.

A standout advantage of the Flatbed Cutter 5070 TNT is its ability to perform cuts on various designs in a single run. This significantly simplifies production and enhances workflow efficiency.

Step-by-Step Guide to Operating the Flatbed Cutter 5070 TNT with Cut Tool CDR Cam

1. Standard Cutting for a Single Design using Cut Tool CDR

-

Design Preparation:

- Create your design using Adobe Illustrator or Corel Draw.

- Incorporate registration marks & QR Code before printing the design. In your design software, use the add mark tool and check add QR Code, then apply. This is crucial for Cut Tool CDR Cam to accurately read your design.

- Save the file in formats suitable for both printing and cutting, ensuring compatibility with Cut Tool CDR Cam.

-

Cutting Preparation:

- Transfer your design file in PLT format to the machine using a USB flash drive. Cut Tool CDR Cam software on the machine reads this format.

- Load your media onto the flatbed, activate the vacuum system to secure it, and manually position the cutting head precisely above the circular registration mark.

- On the machine’s touch screen interface powered by Cut Tool CDR Cam, select Udisk, adjust the copy quantity to match your media, and then tap QR Code to initiate the cutting process. The Cut Tool CDR Cam will scan the QR code and begin cutting.

2. Cutting Multiple Different Designs with Matrix Copy Feature in Cut Tool CDR

-

Input Media:

- Place the printed media with registration marks onto the flatbed and turn on the vacuum.

- Manually position the cutting head at the registration mark of the first design.

-

Matrix Copy Settings in Cut Tool CDR Cam:

- Within the Cut Tool CDR Cam interface, populate the Horizontal and Vertical columns to define the layout of your media pieces on the working area. This tells the machine how many copies and in what arrangement to expect.

- Start the cutting process by using the QR Code scan feature. Cut Tool CDR Cam will automatically direct the machine to continue cutting on the subsequent media pieces according to your matrix copy settings.

3. Cutting Without Printed Designs Using Cut Tool CDR

-

Connect Machine to Computer:

- Establish a connection between the Flatbed Cutter 5070 TNT and your computer via USB or LAN cable. Place your material on the cutting table and activate the vacuum.

- Adjust the cutting and creasing blade pressure according to your material requirements, settings controllable through Cut Tool CDR Cam or machine interface.

-

Cutting Process with Cut Tool CDR:

- Position the cutting head at the edge of your material. Prepare your design in Cut Tool CDR Cam. Utilize the cut/plot by color tools within the software to define cutting paths.

- Click QR Code within the Cut Tool CDR Cam software interface to start the cutting process. Even without pre-printed QR codes, this function in the software initiates the direct cutting based on your design file sent from Cut Tool CDR Cam to the machine.

These three methods will consistently deliver clean and accurate cuts. By following these steps, you can fully leverage all the capabilities of the Flatbed Cutter 5070 TNT and its Cut Tool CDR Cam software.

Watch the Flatbed Cutter 5070 TNT in Action

Conclusion

The Digital Flatbed Cutter 5070 TNT is an advanced solution for maximizing precision and efficiency in your cutting processes. Equipped with superior features like a QR Code scanning system, touch screen control, and Cut Tool CDR Cam software, this machine is capable of handling diverse designs in a single operation, even without printed designs when directly controlled by Cut Tool CDR Cam. While initial operation might seem complex, with the right guidance on using Cut Tool CDR Cam and the machine itself, you can easily master all the essential steps, from design preparation to final cutting. By utilizing this machine and understanding the Cut Tool CDR Cam, you can significantly enhance your production quality and work efficiency.

We hope this tutorial assists you in maximizing the potential of your Flatbed Cutter 5070 TNT!

Get the best quality Digital Flatbed Cutter 5070 TNT from Maxipro

Related Articles:

Testing Paper Thickness Cutting with Digital Flatbed Cutter 5070 TNT [